Built for Safety

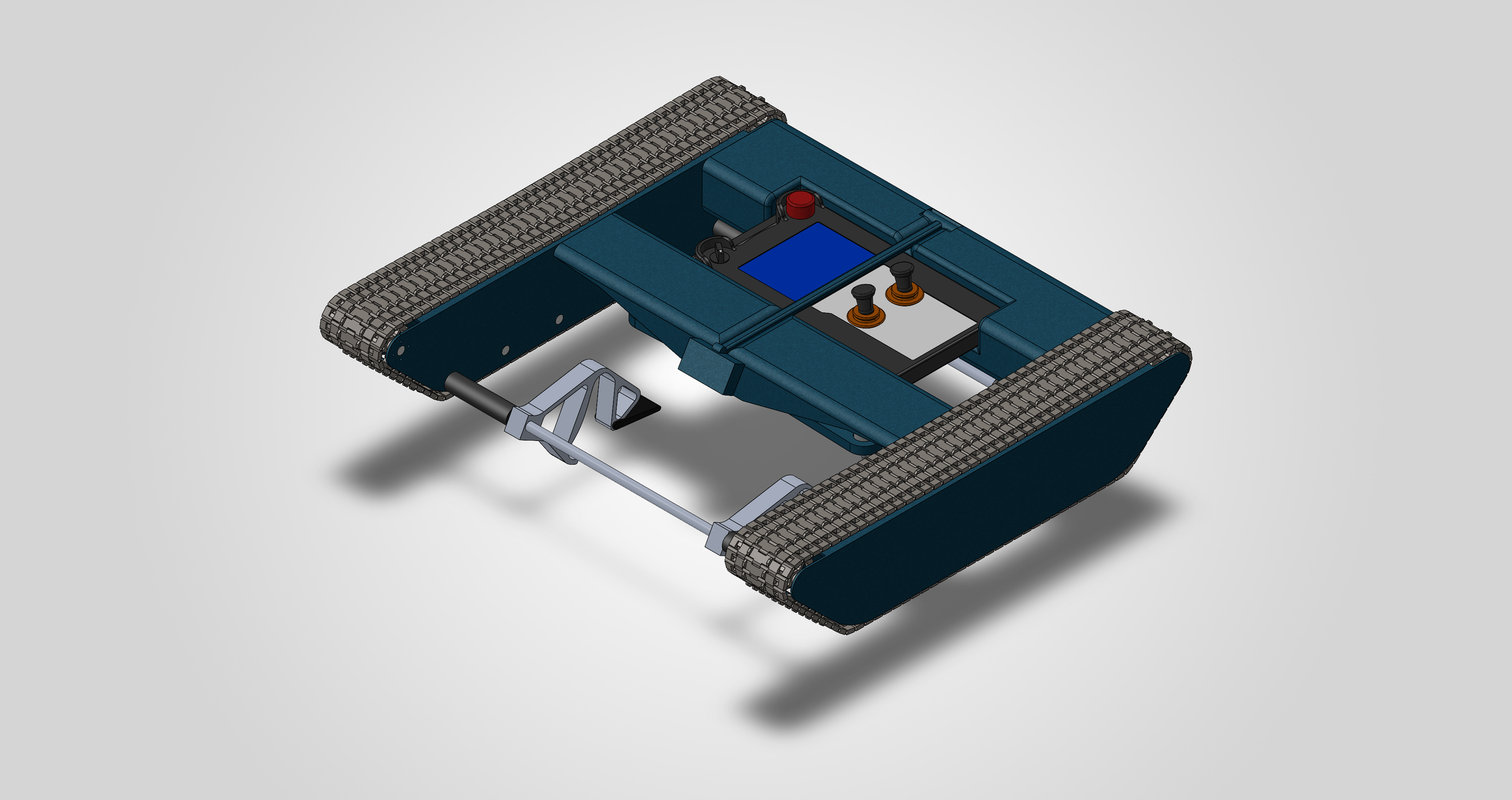

Revolutionize vertical ventilation with VentVortex.

Whether you're equipping a small department or scaling for high-risk operations, our robotic solutions provide remote, reliable vertical ventilation to clear smoke faster, prevent flashovers, and keep your team safe—empowering responders to focus on what matters most.

Our Mission: Safer Responses Through Robotics

At Responder Robotics, we believe firefighters deserve tools that protect them as fiercely as they protect others. Founded with the goal of reducing line-of-duty risks, we develop advanced robotic solutions like VentVortex to enable remote, reliable vertical ventilation—clearing smoke faster, preventing flashovers, and minimizing exposure to extreme heat, structural collapse, and toxic environments.

Safety First: Every design prioritizes reducing injury risks for firefighters.

Innovation for Real-World Use: Built tough for heat, smoke, and rugged deployment—tested in simulated fireground conditions.

Community-Driven: We listen to first responders through feature requests, user stories, and direct feedback to make VentVortex truly useful.

We're just getting started, but we're committed to delivering tools that make a real difference. Join our waitlist, share your experiences, or submit feature ideas—we're building this with you. Together, we can make fireground operations safer for everyone.

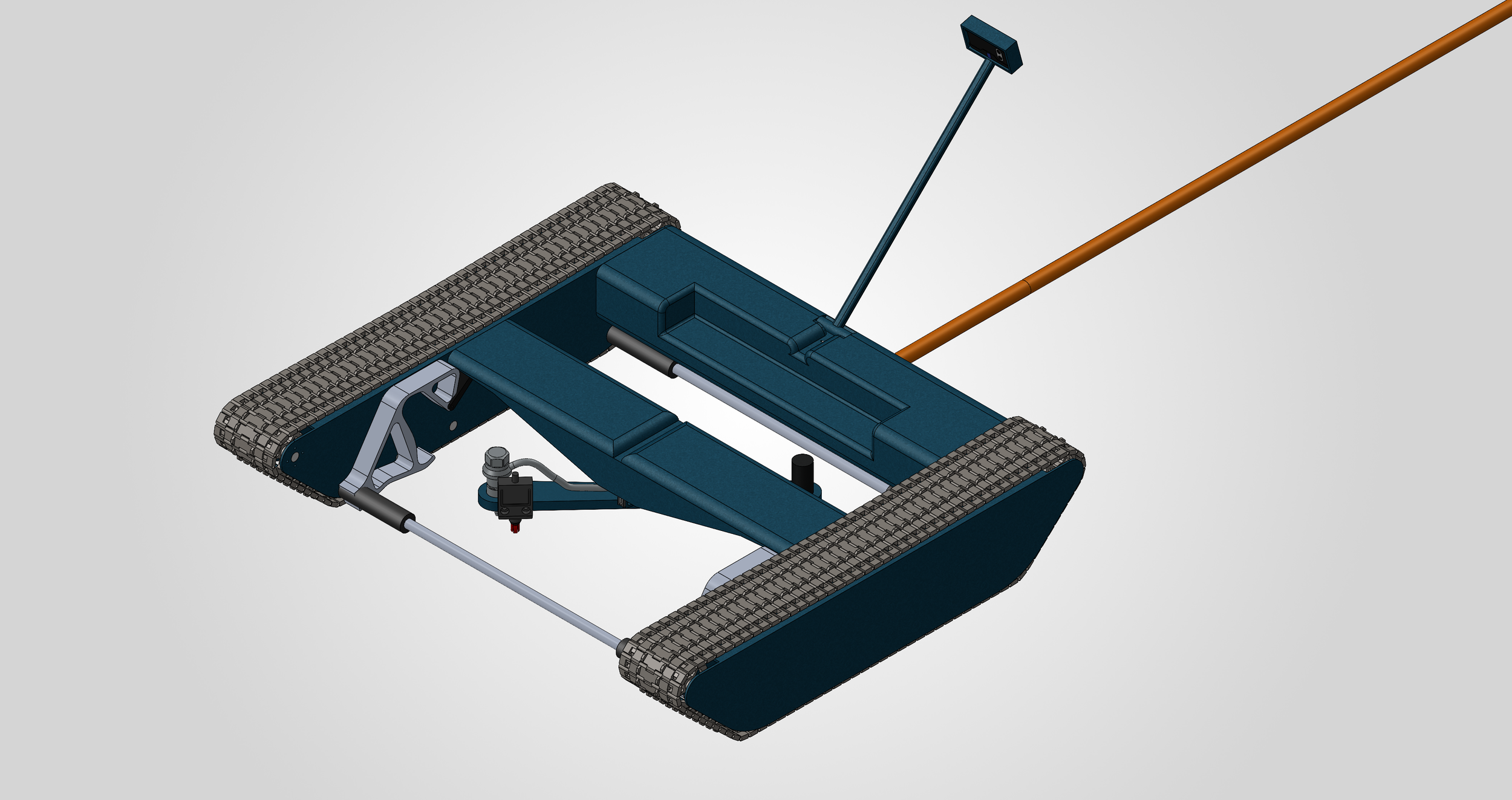

Ladder Transport: Easy Carry with Rollers and Hooks

Watch this cutaway view of the VentVortex robot being effortlessly transported up a ladder using its built-in rollers and secure hooks. Designed for firefighters, this feature minimizes physical strain and enables quick deployment in multi-story scenarios, keeping responders safe while accessing roofs for vertical ventilation.

VentVortex offers flexible cutting capabilities to adapt to the specific demands of any fire scenario, allowing firefighters to create a single vertical ventilation hole or multiple smaller ones for optimal smoke and heat release. This approach can match or exceed the performance of a traditional 4'x4' hole while minimizing structural compromise and enabling safer, faster operations from the ground.

Single Hole Strategy: For focused ventilation in contained fires, VentVortex can cut a large 14-inch circular hole to rapidly vent heat and gases, reducing flashover risks and improving visibility without extensive roof damage.

Multiple Hole Configurations: In larger or more intense blazes, deploy several circular holes or elongated ovals (future upgrade) to distribute airflow evenly. This modular method achieves equivalent or superior ventilation to a 4'x4' opening by creating customizable patterns—e.g., a cluster of circles for broad coverage or ovals for targeted linear vents—while preserving more of the roof's integrity.

Versatile Ventilation Options with VentVortex

Meet the Founder

I'm Ryan Giovacchini, a robotics engineer with a Master's degree in Robotics Engineering from Worcester Polytechnic Institute (WPI). With over a decade of hands-on experience in designing, building, and testing robotic systems, I'm passionate about creating technologies that make the world safer—especially for those on the front lines like firefighters.

My career has taken me through innovative roles at companies like Sam's Club (Walmart), where I invented and patented a touchless health screening kiosk that saved an estimated $19 million in labor costs and was rolled out to 600 U.S. locations. At Perrone Robotics, I led hardware design for autonomous vehicles, and at Integrated Construction Enterprises, I generated over 35 patentable concepts, built functional prototypes for construction applications, managed cross-functional teams, and helped secure an SBIR grant from the National Science Foundation for a patented painting system. Across these experiences, I've collaborated on 17 patents, conducted field trials, and honed my skills to solve complex problems.

Recently, after being laid off from Walmart just weeks following paternity leave for my baby girl, I've channeled my energy into founding Responder Robotics. This venture is deeply personal, driven by a commitment to prevent firefighter injuries, structural damage, and tragedies through cutting-edge solutions like VentVortex, our remote-controlled robot for safer vertical ventilation using waterjet technology. I've built multiple robots from scratch, including a fully custom paint robot, and I'm excited to bring VentVortex to life.

At Responder Robotics, I'm dedicated to transparent development, community feedback, and real-world impact. Whether it's reducing flashover risks or empowering departments with reliable tools, my goal is to deliver user-centered robotics that save lives. Feel free to connect—I'm always open to ideas from fellow innovators and first responders.

Ryan Giovacchini, Founder of Responder Robotics

FAQs

-

VentVortex is currently estimated to weigh between 50 and 60 pounds in its final production configuration. This weight range balances powerful cutting performance with portability, allowing for manageable deployment by a single firefighter. Exact weight will be confirmed during final testing and certification phases prior to shipping in Q1–Q2 2027.

-

VentVortex is designed with integrated rollers and ladder hooks for safe and efficient vertical transport. The rollers allow smooth movement up the rails of the ladder, while the specialized hooks securely attach the unit to ladder rungs during ascent. This system enables a single firefighter to position the robot quickly and safely without excessive physical strain, even in multi-story structures.

-

The current VentVortex system features a high-pressure waterjet cutting module capable of creating a clean 14-inch circular opening in standard building materials for optimal ventilation. Additional shape-cutting capabilities (e.g., squares, rectangles, or custom patterns) are planned as a future software upgrade. We’re actively gathering feedback from responders to prioritize the most useful configurations.

-

Pre-orders open in April 2026 with a refundable deposit. Full production units are expected to ship in Q1–Q2 2027. We’re committed to thorough testing and manufacturing setup to ensure reliability in real-world fireground conditions. Join the waitlist for priority updates and early pricing.

Help Shape VentVortex: Submit Your Feature Requests.

We value the insights of firefighters and first responders like you. What enhancements would make VentVortex even more effective on the fireground? Share your ideas—from improved controls to added durability features—and help us build a robot that truly meets your needs. All submissions are reviewed by our team, and we'll keep you updated on progress.